In-Process Particle Sizing

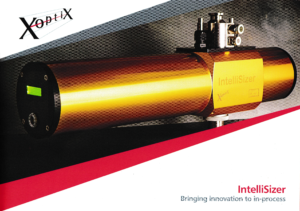

PPDS are pleased to offer in-process particle sizing from our partner Xoptix.

By combining the latest technology with the well-proven particle induced laser diffraction principle, Xoptix Ltd has developed a compact and robust instrument for real time in-process particle sizing.

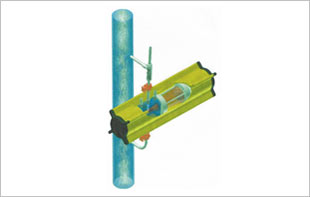

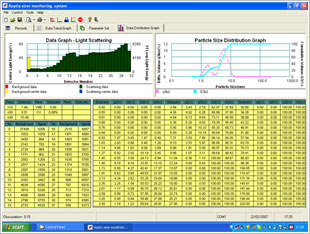

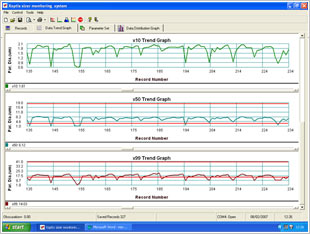

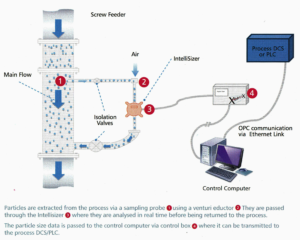

The range of Xoptix instruments provide continuous measurement of particle size by extracting a small sample from the process line, presenting it for analysis before routing it back into the process. The particle size data is collected and can be displayed on a PC or can be exported to the customers control system enabling process control within preset limits.

The instrument can be used to measure the size distribution of particles either as a dry powder or in suspension as a slurry.

Typical applications include:

- On a milling or classification system in the airstream between the classifier outlet and cyclone/filter inlet.

- On a milling or classification system in a gravity chute below the cyclone/filter discharge.

- On a screening process at the “unders” discharge – where the instrument would immediately raise an alarm in the event of screen failure.

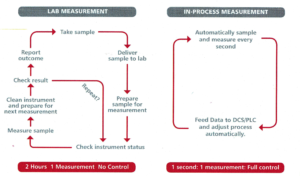

At present, the above processes are usually monitored by manual sampling of the product by the plant operator perhaps once or twice in a shift. The sample is taken to the laboratory for analysis either by the laboratory technician or perhaps by the plant operator himself. The result is then available at some point later (at best in minutes but sometimes hours) and the process parameters are then adjusted as appropriate.

With the Xoptix instrument the plant operator will have a display of particle size data from one second to the next. Trends in the particle size distribution can be seen and adjustments to the process parameters can be made (either manually or automatically) before any deviations reach specification limits. As a result the process can operate closer to the specification limits, giving higher throughputs and lower specific power consumption.

In-process particle sizing using laser diffraction is not new technology but until now the price has been an inhibiting factor. With the Xoptix instrument, in-process particle sizing is affordable. So can you afford not to consider it for your process?

We would be delighted to discuss any potential application that you may have and on site demonstrations can be arranged where appropriate.